The new DMG MORI CTX alpha 500 extends the machining center at Jüke with a high-precision universal turning machine of the latest generation. Top modern design and an enlarged working area with the same footprint ensure that the specialists at Jüke are even more pleased to work with the new machine.

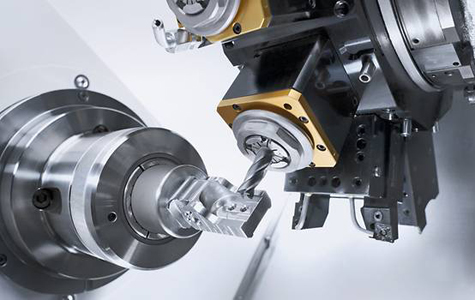

The alpha 500 can process workpieces up to 240 mm in diameter and up to 500 mm in length. The counter spindle and the Y axis provide additional added value. The highest stability and accuracy is given with this innovative machine. This is guaranteed by robust guides and a direct measuring system in the X axis.

The operation is carried out on the latest digital level through graphic dialog programming and real-time simulation. The monitoring possibilities of the machine are manifold and include, for example, a tool monitoring system or a messenger for digital live monitoring of the machining processes. The alpha 500 is also already equipped with the option of a bar feeder. This is a step towards automation, as it is possible to produce larger series efficiently without manual intervention.

With this investment, Jüke is expanding its already top-class machine park with a further highlight and is well positioned for the future in high-precision manufacturing.