For a special project in medical technology involving the very precise and reliable temperature control of a patient during surgery, two experienced employees have qualified in soldering in a practical technical course and have been certified by passing a final examination. From this point on, Jüke is able to produce special cooling systems that are environmentally safe and can be operated according to the strict regulations for medical products.

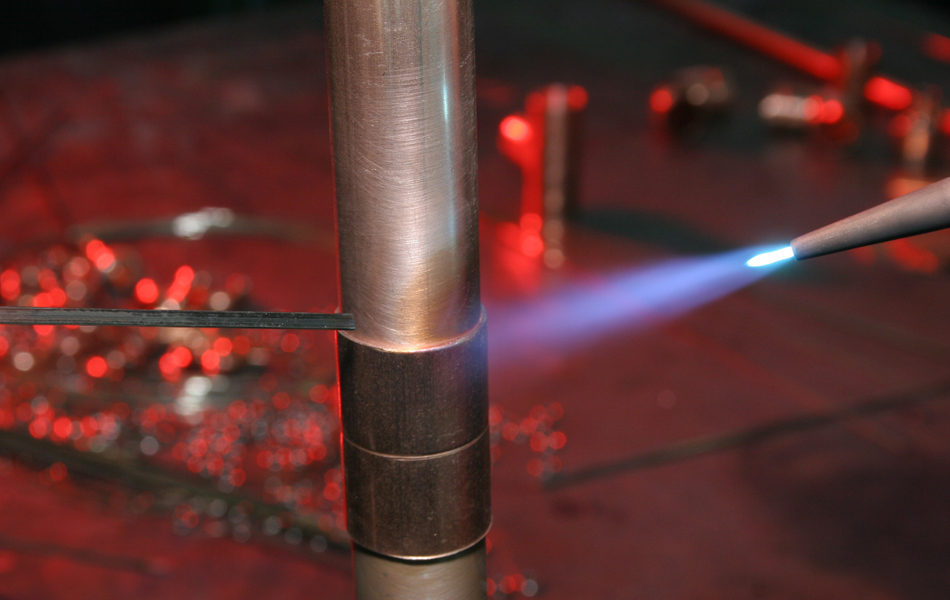

For the high requirements in soldering for the substance-to-substance joining of Cu-Cu connections for cooling technology, both the theory had to be learned and tested in practice through exercises. Knowledge of different solder materials, the materials to be soldered as well as knowledge of the special features of cooling technology and the properties of coolants play an important role here. Careful production of such equipment ensures that no coolant can escape into the environment through leaks or improper handling of solder and soldering material.